A few weeks ago, I went to a new client’s house to measure up for a hardpoint in their living room. It will be used for rope bondage and similar suspensions.

The first step is to get access to the joists in the ceiling. Since the living room was on the first floor, I was able to gain access through the loft. Being a late Victorian building, the joists up there were hefty and solid, and didn’t need much reinforcement. Armed with my measurements, I headed for the workshop where I would fabricate a bracket.

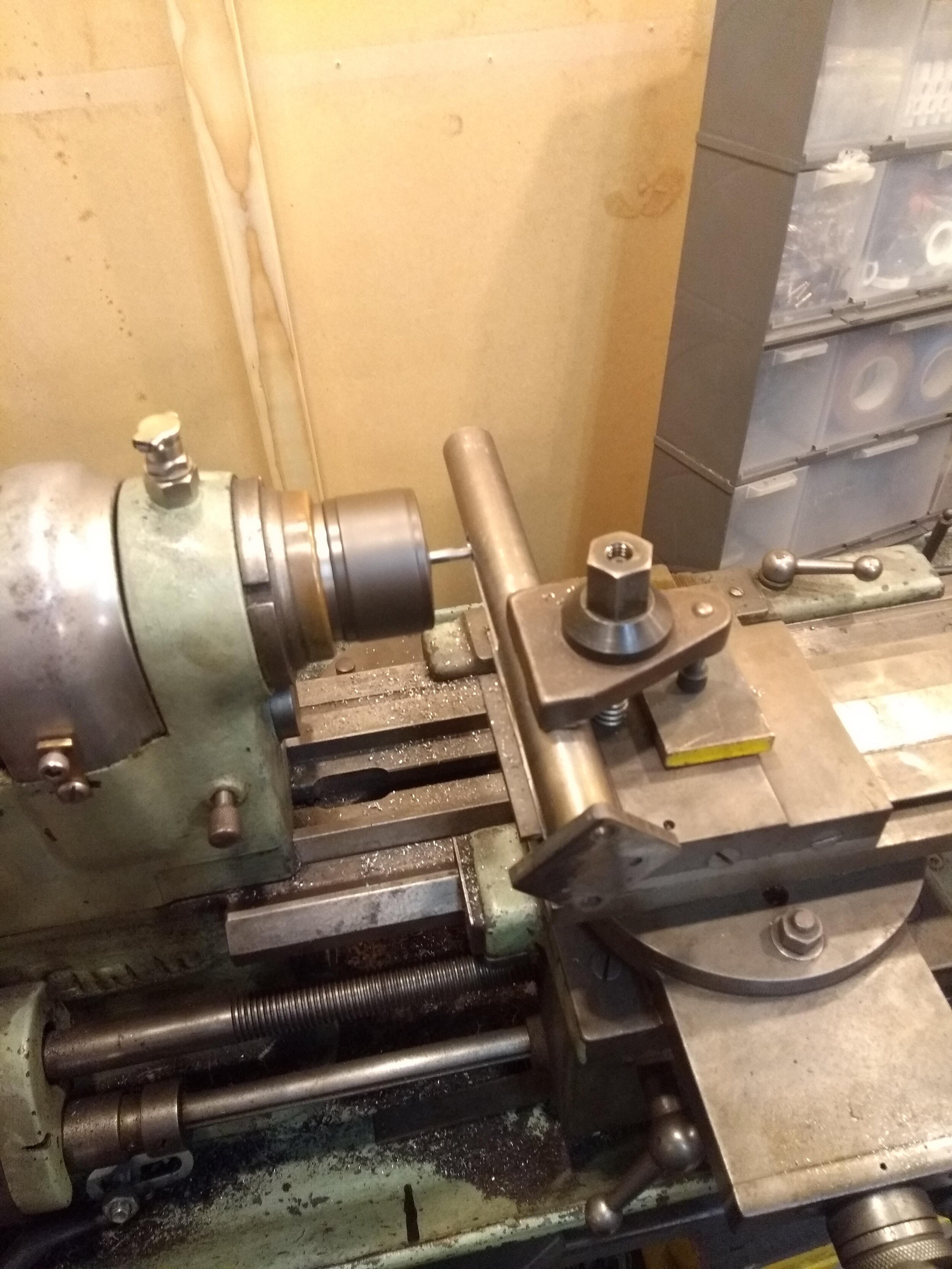

This process is described in detail in a series of tweets HERE, but I’ll explain roughly what I did- starting with a piece of 60x6mm steel angle, I drilled it for two mounting holes, and one hole for the hardpoint itself. I then welded in some gussets for extra support. These were probably unnecessary, but I like to overbuild on projects like this.

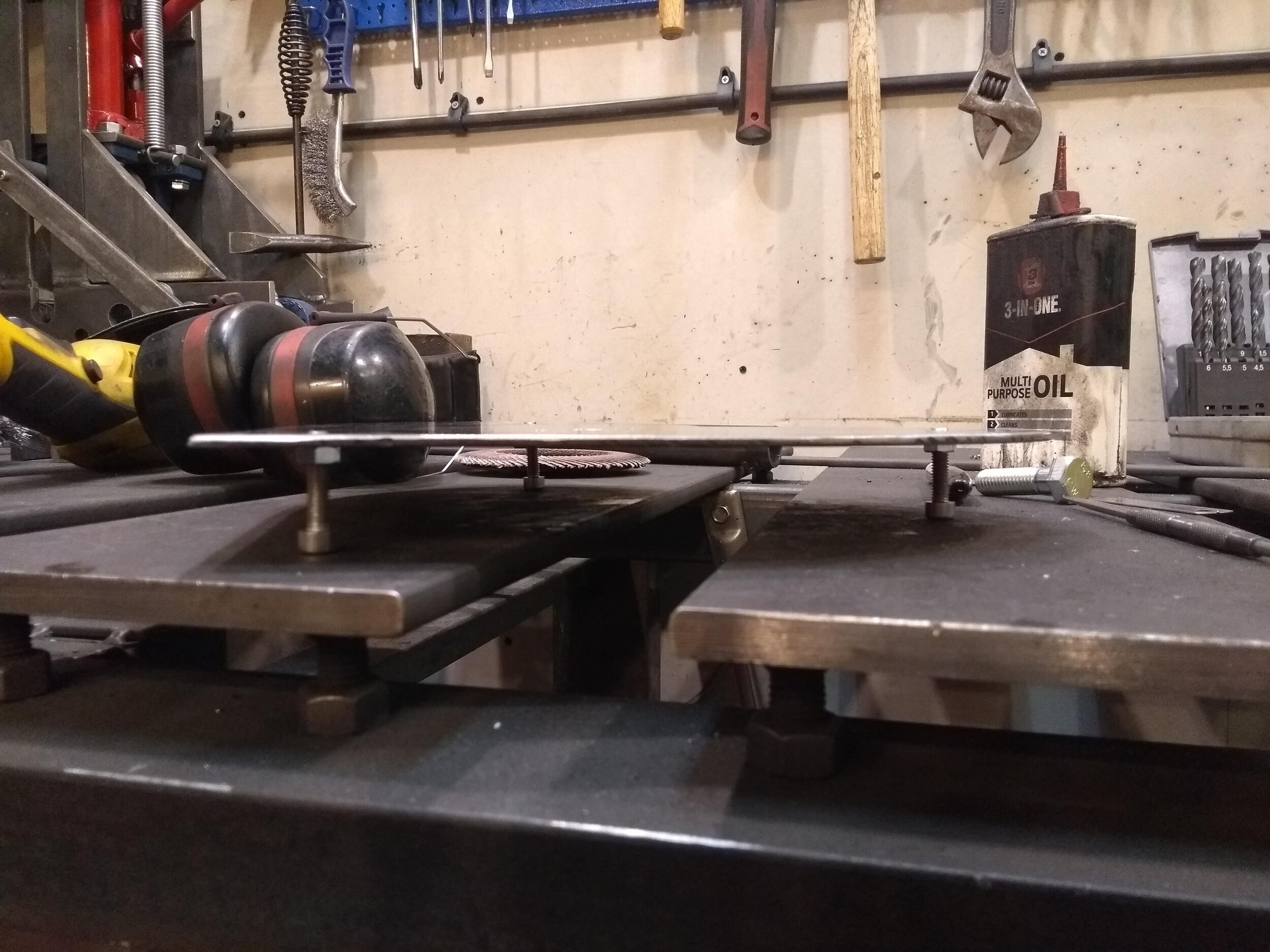

With the bracket made, I got to work on the assembly that will be the actual attachment point in the room below. This was a piece of M12 studding (threaded rod) with a ring nut on the end, held in place with threadlocker (a specific type of glue) and a lock nut. The threaded portion would then run up through the ceiling, through the bracket, through a thrust bearing that would allow it to spin, before being fastened with a nut. Since it was able to rotate, it was necessary to ensure that the nut holding it in place could not come undone. I did this with a locknut and a castle nut, which has grooves cut in it. A hole drilled through the stud itself allows a split pin to sit in one of these grooves, preventing the nut from turning. You can see a bit more detail HERE.

With all that done, the finished assembly looked like this.

With the fabrication portion of the project complete, the next day I headed back to the client’s house. Installation was pretty straightforward.

First, I went back into the loft and took up the relevant floorboard. Then I removed the insulation (a very old loose kind) with a vacuum.

The large timbers running top to bottom in the image are the joists. The narrow strips of timber running side to side are laths, which were used to hold up plaster in the days before plasterboard. Having measure downstairs to find the location of the hardpoint, I put the bracket in the correct place and marked the hole for the stud. I then drilled it with a small drill to confirm the location. With the client happy that it was in the right place, I drilled the hole out to accept the stud, and with the clients help, temporarily fixed the stud in place.

I then put the bracket over the stud, which allowed me to locate the holes in the joist that it would bolt through. I drilled them out, bolted the bracket in place, and then adjusted the stud to final height and added the lock and castle nuts. There are also a pair of lock nuts between the ceiling and the bracket to stop the ring nut from being pushed up into the ceiling and damaging the plaster.

Here’s the bracket bolted in place:

Next I added some reinforcement between the joist with the bracket on and those on either side. As weight is added to the hardpoint, the joist might want to sag a little. It can’t really sag in a straight line, it’ll try to twist, and so adding some pieces of timber between it and the other joists prevents this. These are just nailed in place. For some reason, these pieces of timber are called noggins.

That’s all the structural parts done, but I needed to ensure there was easy access to the bracket, for inspection and maintenance, and also because the client wanted the option of removing the stud. I made a hatch by just cutting the floor board into sections and drilling a hole to pick the hatch up by.

With all that up in the loft, all that’s on show in the living room is the ring nut:

And that’s that!

If you want a hardpoint installing in London, get in touch! Here are some things to consider:

I’ll need access to the joists. This is usually easiest by going in from above. If that’s not possible, I’ll have to make an access hole in the ceiling, which will then need replastering.

If your house is more modern it may be necessary to reinforce the joists further.

This hardpoint was designed for single point suspension. If you wanted one for a swing or similar, with higher dynamic loads, it would be necessary to do further reinforcement.

This installation was pretty straightforward, and I quoted £150 for it in mid 2022. Naturally a different situation, particularly one of those listed above, may affect the price.